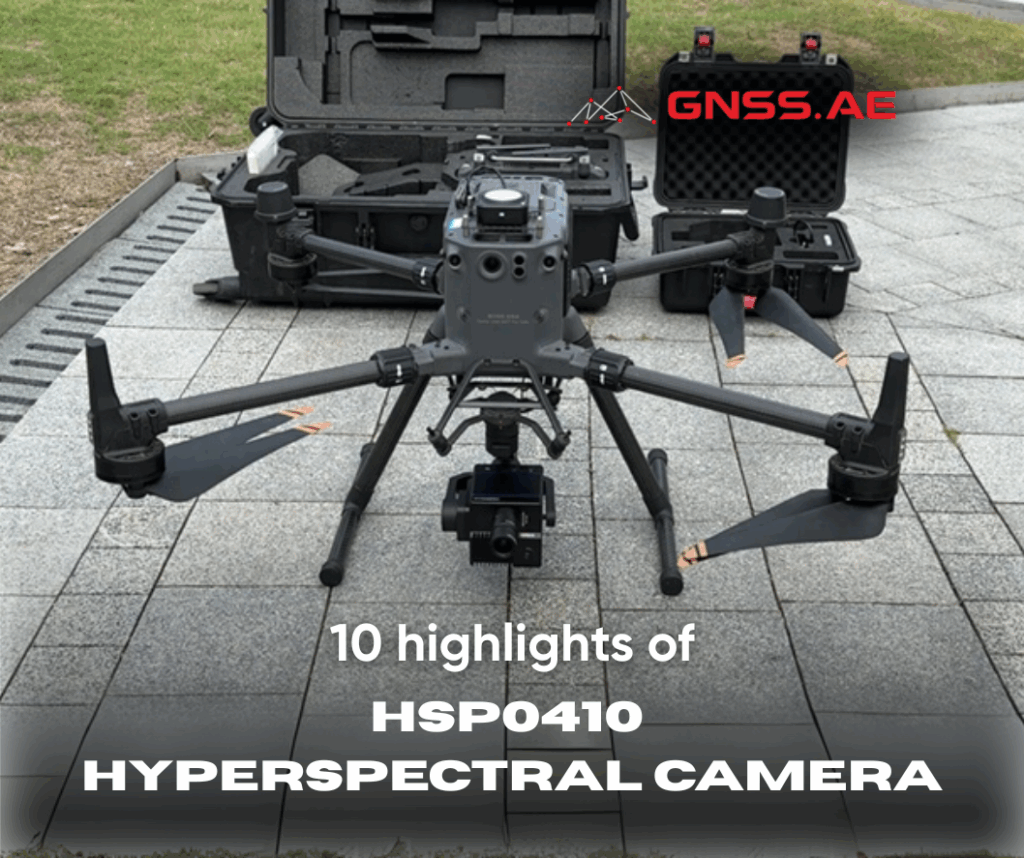

The HSP0410 utilizes a novel optical-mechanical system, resulting in a compact and lightweight design. Its integrated design makes it compatible with the X-Port and DJI M350 RTK, enabling quick and safe flight without modification.

The X-Port gimbal provides camera mounting, power, communication, and attitude control, eliminating the need for external RTK antennas, assembly and disassembly of integrated components, or complex pre-flight commissioning. Plug-and-play operation allows single-operator operation to be operational in just two minutes.

HSP0410 has two working modes: swing sweep and push sweep:

(1) The pan-sweep mode supports pan-sweep in any range from -20° to +110° (0° vertical to the ground, positive in the upward direction and negative in the downward direction), and can collect various targets such as inclined and vertical targets. It is particularly suitable for scenarios such as tree vertical profile surveys, cultural relics protection and restoration, and building facade monitoring.

(2) The push-broom mode camera is three-axis stabilized to the ground, which is suitable for large-area aerial photography operations. In the route mode, it automatically flies and collects data while flying. The operating efficiency is more than 5 times higher than that of hovering sweeping.

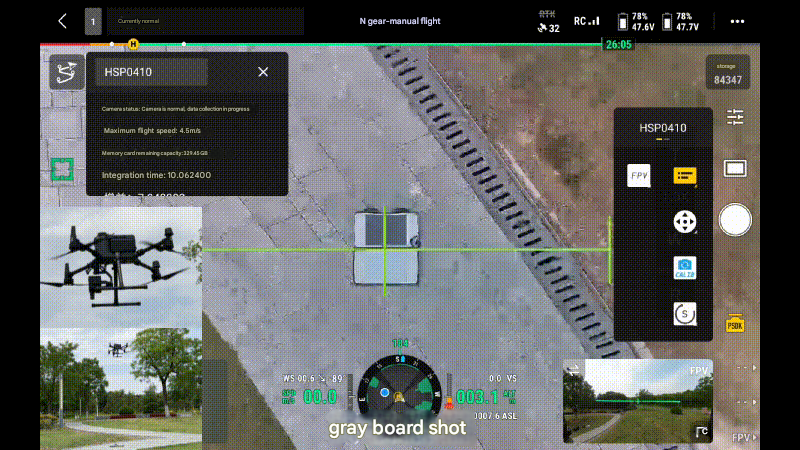

Working mode switching, status monitoring, automatic gray plate shooting, parameter setting, route planning, etc. can be completed on the remote control Pilot, greatly improving the convenience of operation.

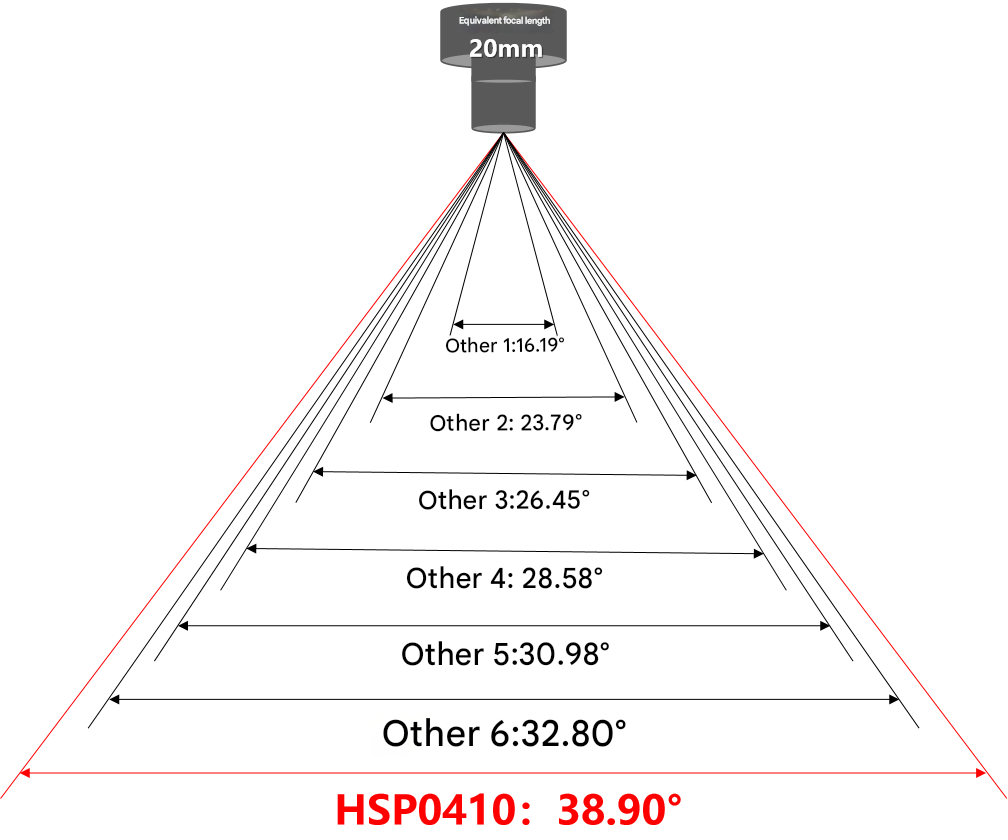

Long focal length and large field of view are the best of both worlds in remote sensing instrumentation. Thanks to the longer slit design, the HSP0410 achieves a field of view of 38.9° at a focal length of 20mm, achieving higher operating efficiency under the same spatial resolution conditions.

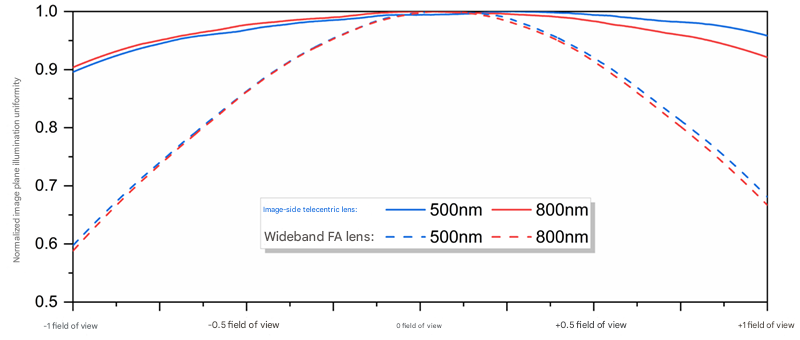

Image plane illumination uniformity directly affects the dynamic range of remote sensing instruments. Commonly used wide-band FA lenses generally have an illumination uniformity of around 0.6 across the entire field of view, and the pupil does not fully match the spectrometer. The HSP0410 uses a self-developed image-space telecentric lens with an illumination uniformity better than 0.9 across the entire field of view, which fully matches the spectrometer and increases the dynamic range of the entire instrument by more than 1.5 times.

With its long focal length, large field of view, wide dynamic range, and active spectral radiation modulation, the HSP0410 can effectively acquire fine spectral images with high geometric resolution and high signal-to-noise ratio of high-reflective and low-reflective objects such as vegetation, water bodies, soil, and impervious surfaces in the same field of view.

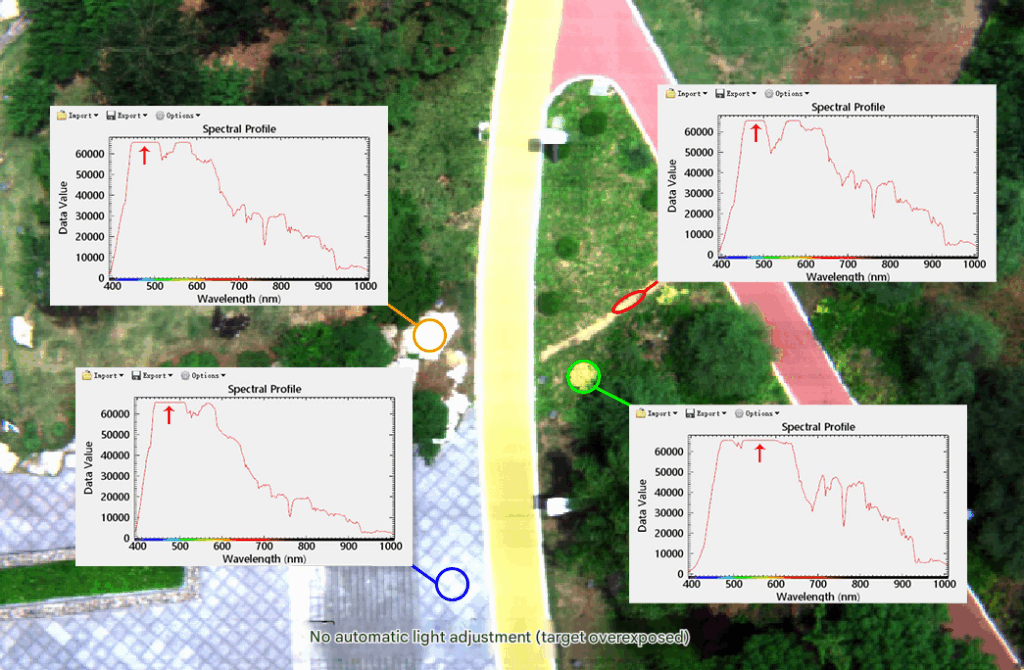

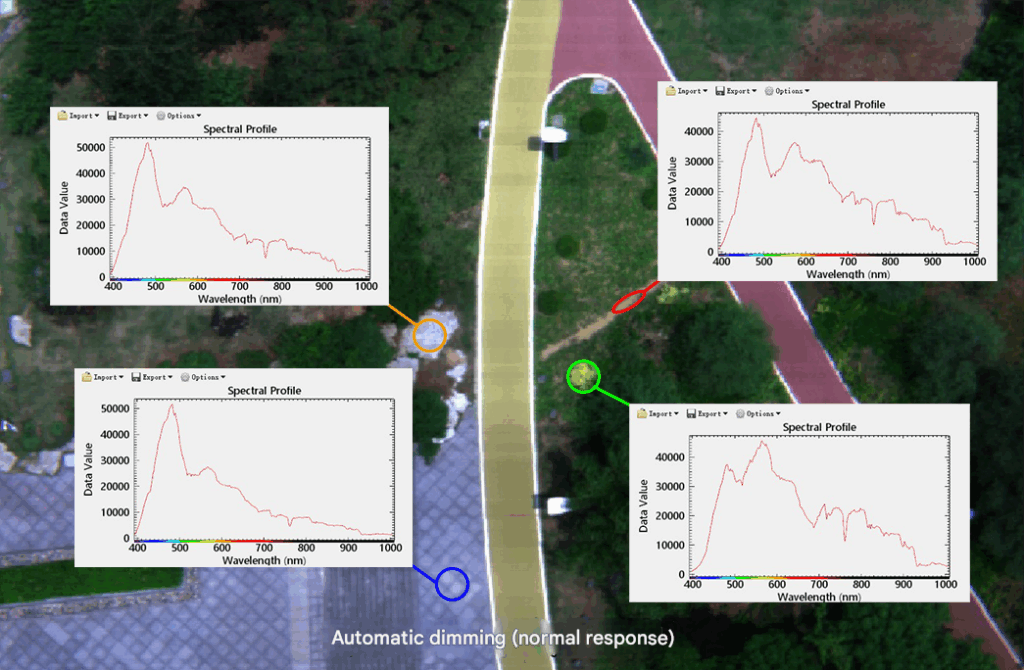

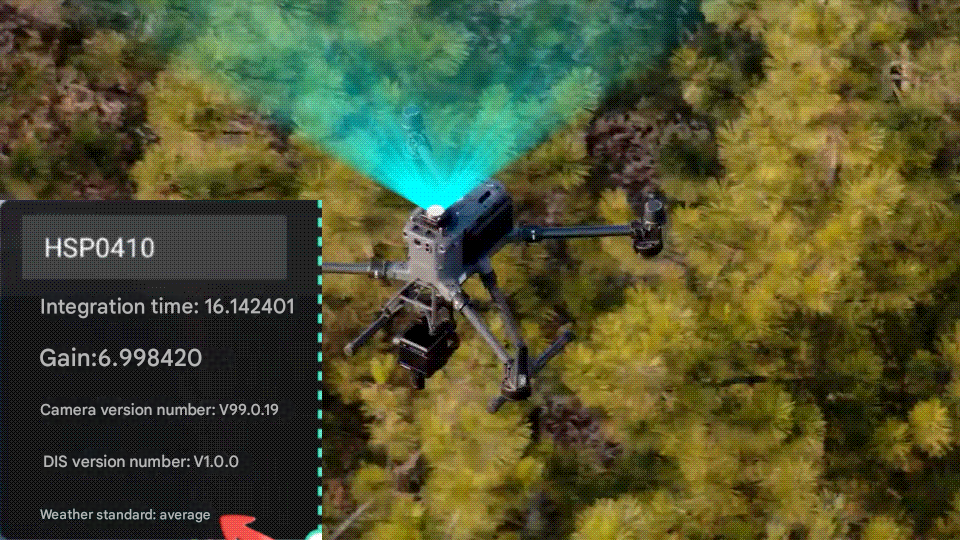

The camera has a built-in automated “metering-dimming-exposure” program, coupled with an intelligent dimming algorithm that prioritizes signal-to-noise ratio across the entire field of view and full band, and suppresses high/low light, to achieve automatic adjustment of exposure parameters such as integration time and gain.

The optimal combination of full field of view, full-band gain, and integration time is achieved within milliseconds, enabling the camera to perform high signal-to-noise ratio spectral imaging in the best condition. This eliminates the need for tedious operations such as pre-flight metering and relying on experience to set fixed exposure parameters, ensuring that targets in complex scenes are not too dark or overexposed, essentially improving data quality.

The accuracy of spectral measurement is the soul of hyperspectral cameras and indirectly affects the accuracy of radiation measurement. During long-term field use, due to changes in factors such as vibration, temperature, and air pressure, hyperspectral cameras will inevitably experience spectral line drift. In the past, they generally needed to be returned to the factory regularly for laboratory spectral calibration and correction.

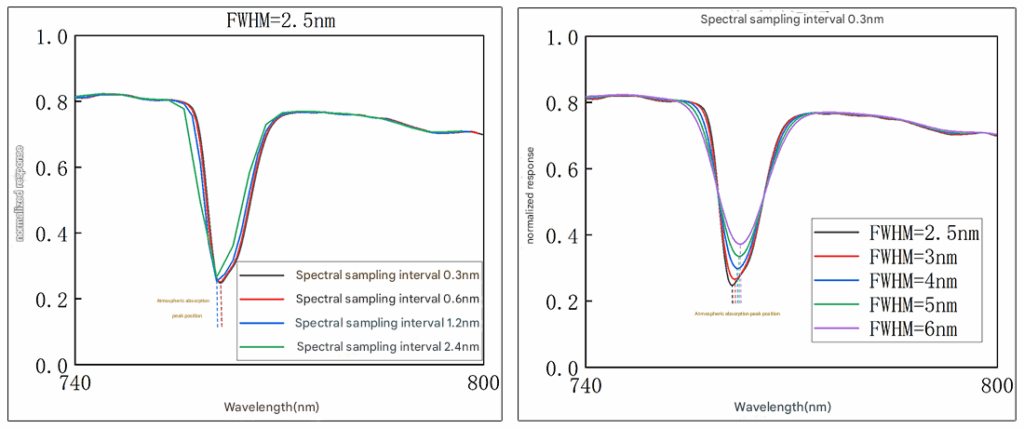

Thanks to the HSP0410’s high spectral resolution and signal-to-noise ratio, it can stably capture the exact position of extremely narrowband atmospheric absorption peaks. Combined with the high-precision spectral calibration matrix, self-developed spectral correction algorithm, and fully automatic data preprocessing software provided before each camera leaves the factory, it can autonomously detect and automatically correct possible tiny spectral line drifts, keeping the spectral measurement error within ±0.3nm.

Bonus: Accurately capturing atmospheric absorption peaks is also an effective way to test a hyperspectral camera’s spectral resolution and measurement accuracy. This is because as the FWHM or spectral sampling interval increases, the accuracy of the atmospheric absorption peak shape and position measurements also deteriorates.

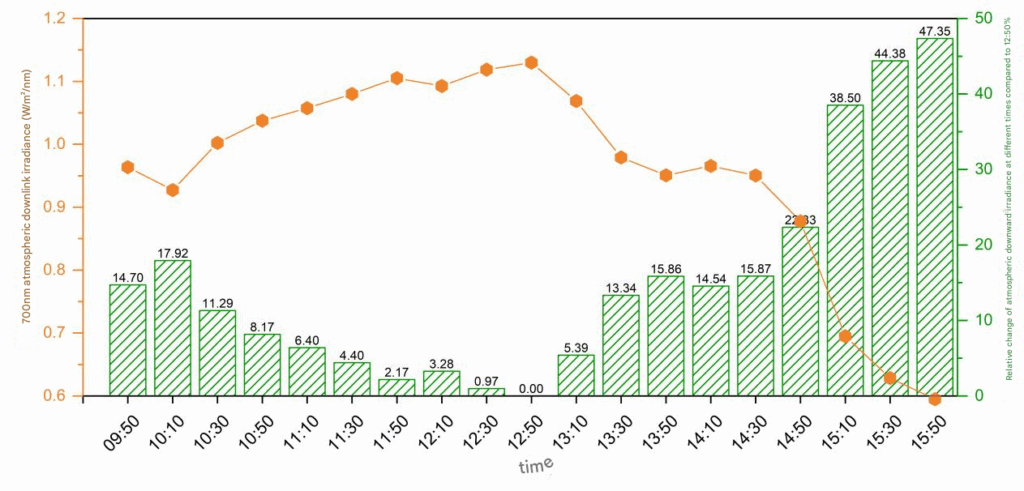

“Assuming that the sunlight level remains constant for a short period of time” is a generally accepted “typical operating condition” in the field of drone-mounted hyperspectral remote sensing. But is this actually the case? Not at all!

The measured results show that even at noon on a clear day, the downlight irradiance may still vary by more than 10% within 30 minutes due to changes in the solar altitude angle. The lighting environment in cloudy weather will fluctuate significantly. Ignoring these changes will seriously affect the accuracy of radiation measurement based on the gray-plate transfer method, resulting in a lack of consistency in the time series of the data.

The HSP0410 comes standard with a downlink light sensor (DIS), which can simultaneously sense the radiation changes of the sun’s downlink light across the entire wavelength band. Quantitative correction can be performed during the data preprocessing stage to ensure more accurate radiation measurement.

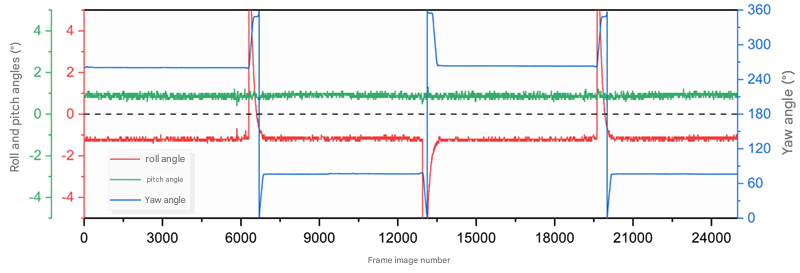

Since the HSP0410 was released, people have been curious about how it achieves such high geometric imaging quality in airborne push-broom mode. After all, the image quality of most current airborne hyperspectral cameras in this mode is unsatisfactory. This is due to the multiple benefits of the carrier, gimbal, and algorithm during the data acquisition process:

(1) No external high-precision RTK is required. Only the attitude information of the X-Port gimbal is used. The closed-loop control algorithm can ensure high-precision three-axis ground stabilization in push-broom mode. Compared with locking any one axis, the camera attitude is less affected by the drone attitude.

(2) The camera automatically receives the 100Hz high-precision POS information output by the DJI M350 RTK drone and synchronizes the frame with the image to ensure that the image matches the POS information and assists in geometric correction during the data processing stage.

The lateral overlap rate of visible light aerial photography is generally between 55% and 60%, while the lateral overlap rate of multispectral remote sensing is generally not less than 70%. Why can the HSP0410 hyperspectral remote sensing achieve a lateral overlap rate as low as 30%? On the one hand, push-broom hyperspectral imaging is frame-by-frame, and each frame conforms to the central projection imaging geometric model. There is a certain geometric relationship between each frame, and the image strips are relatively longer, which is more conducive to the image matching algorithm to measure corresponding points between routes. Therefore, the overlap rate between routes can be minimized during actual flight. On the other hand, thanks to high-precision ground pointing and stable push-broom, the original data has less misalignment and distortion, and a lateral overlap rate of 30% can meet the requirements for establishing geometric constraint relationships between adjacent frame images. Compared with the high-overlap rate acquisition mode of 70%, the data acquisition efficiency is more than doubled within the same time.

Data recovery is the final stage of field data collection. Existing hyperspectral camera products usually have built-in hard drives, and data must be copied while powered on. There is a risk of data loss due to abnormal power outages or disconnections.

The HSP0410 camera uses the plug-and-remove external storage media method of digital cameras, employing high-speed CompactFlash cards with VPG400 certification, which guarantee a sustained write speed of at least 400 MB/s. After landing, the camera can be powered off and the card can be removed to recover data. This allows for flexible, uninterrupted card replacement, especially for large-scale, continuous operations.

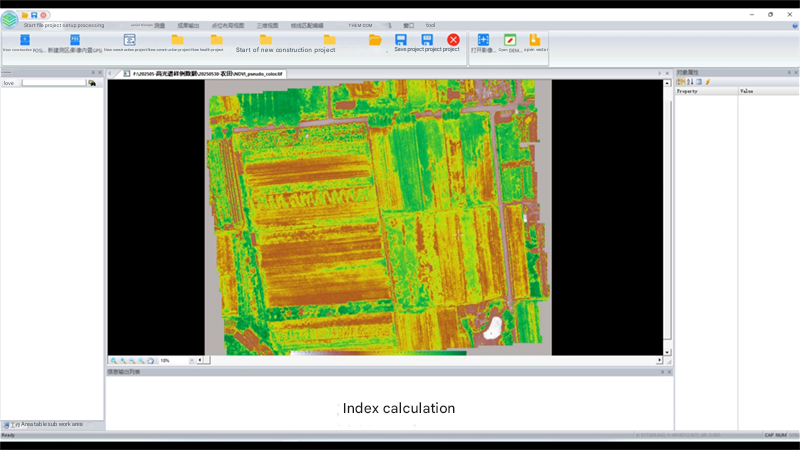

The camera’s accompanying data processing software uses a process-based, automated processing logic. One software can complete the entire data processing process, including automatic route segmentation, feature point matching, aerial triangulation & regional block adjustment, orthorectification and mosaicking, and reflectivity correction.

The original route segmentation and inter-strip aerial triangulation algorithm can realize the orthorectification of route images and ortho-mosaicing without elevation and base map conditions, reducing dependence on external data and the degree of manual interaction. Through simple interface operation, the software can complete spectral, radiometric and geometric data correction, and output high-precision spliced global spectral reflectance images, comprehensively improving the user experience.

(Actual test conditions and results: Using an Intel Core i9-9900K 5.0GHz processor, 64GB of RAM, and a 2TB SSD graphics workstation to process 50GB of raw data (flight altitude 120m, single flight coverage area 700 mu), the full-process processing time was ≤40 minutes.)