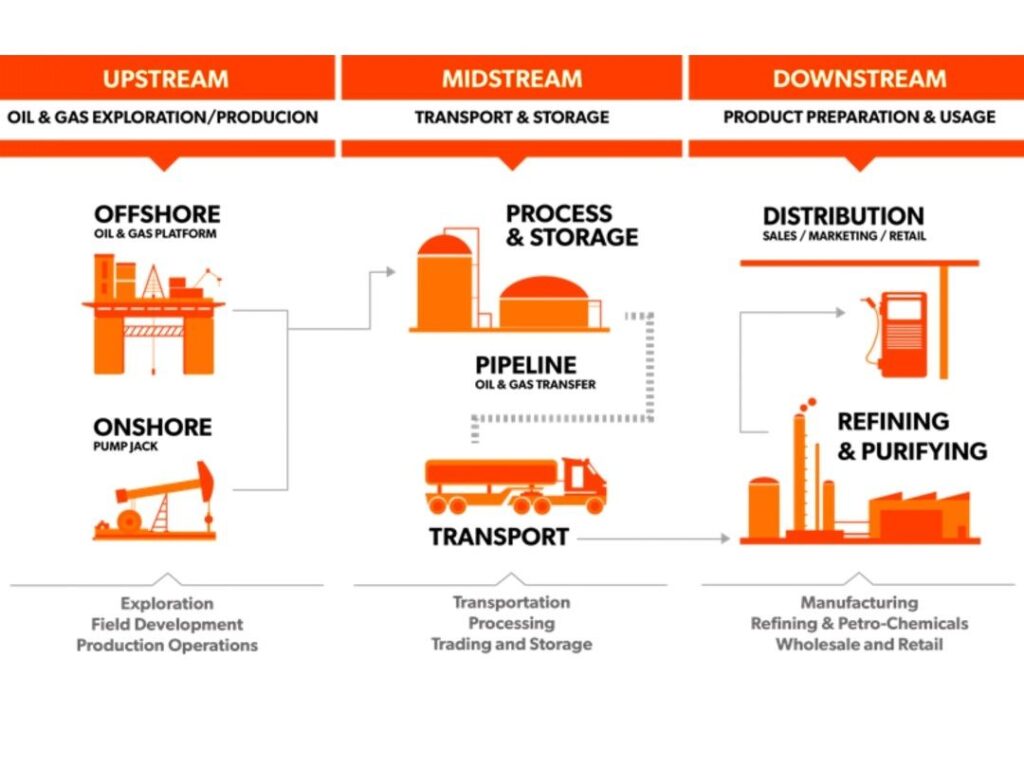

LiDAR (Light Detection and Ranging) has emerged as one of the most transformative geospatial technologies in the oil and gas industry. By emitting millions of laser pulses and measuring their return times, LiDAR generates dense 3D “point clouds” that capture the physical environment with exceptional accuracy. These point clouds form the basis for highly detailed digital models, enabling better decision-making across the upstream, midstream, and downstream sectors. From de-risking exploration to ensuring pipeline integrity and optimizing refinery operations, LiDAR is redefining how data supports infrastructure, safety and efficiency.

In the exploration and production (E&P) phase, uncertainty and high capital risk demand robust planning tools. Traditionally dominated by seismic surveys, upstream reconnaissance now increasingly integrates airborne LiDAR to complement and refine subsurface imaging efforts.

Airborne LiDAR surveys—deployed from fixed-wing aircraft or long-range UAVs—produce high-resolution Digital Elevation Models (DEMs). These serve as a critical foundation for seismic survey design, ensuring geophones are optimally positioned based on precise topography. This improves data fidelity and minimizes errors in subsurface interpretation. For a deeper explanation of how DEMs, DSMs, and DTMs differ and their roles in geospatial analysis, refer to our earlier article.

LiDAR reveals subtle terrain features—minor slope changes, drainage anomalies, and linear surface expressions—that can indicate hidden geological structures like faults or ancient reefs. In regions masked by dense vegetation or glacial deposits, these features are otherwise invisible. LiDAR’s vegetation-penetrating capability allows geologists to detect these cues, significantly improving prospect targeting.

In coastal regions like the Fujairah Emirate in the UAE, LiDAR and remote sensing have proven essential for addressing terrain-related challenges beyond exploration—particularly in environmental and site planning. The Fujairah Research Center, highlights the application of LiDAR, satellite imagery and GIS tools in monitoring coastal erosion, a growing threat to the emirate’s infrastructure and ecosystems due to sea-level rise, wave activity and human development. By generating high-resolution digital elevation models (DEMs), LiDAR enables precise tracking of shoreline changes, sediment movement, and erosion hotspots over time. This data supports proactive mitigation strategies and informs the placement of critical infrastructure such as access roads, well pads, and staging areas in geologically sensitive zones. For upstream operations in coastal or low-lying regions of the MENA area, such remote sensing integration is vital for minimizing environmental risk and ensuring long-term site viability.

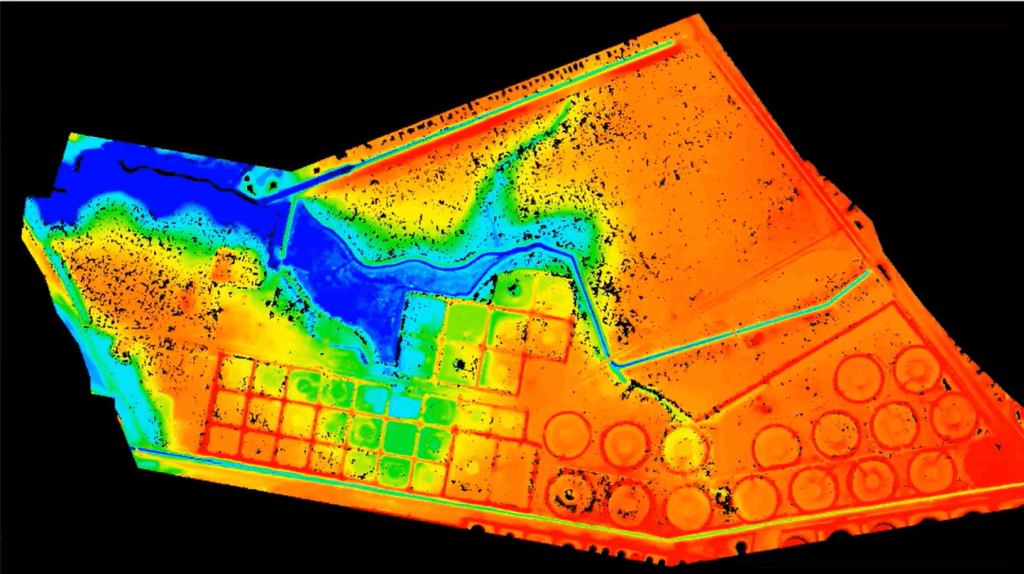

Midstream infrastructure—pipelines, pumping stations, and terminals—forms the connective tissue of the energy network. LiDAR plays a pivotal role in planning, constructing, and maintaining this infrastructure, offering unmatched accuracy in terrain modeling and hazard detection.

During the design phase, LiDAR-derived elevation data enables route optimization. Engineers can evaluate multiple alignment scenarios, balancing construction feasibility, slope stability, and hydraulic efficiency. These insights help minimize costly bends, reduce pumping energy requirements, and improve safety compliance—all while lowering capital expenditure.

Beyond construction, LiDAR is instrumental in ongoing risk management. Periodic aerial LiDAR scans allow operators to detect changes in terrain elevation that may signal slope movement, erosion, or subsidence. Even minor topographic shifts can be early warnings of landslides or ground instability that threaten pipeline integrity. Early intervention informed by these insights prevents catastrophic failures and environmental damage.

LiDAR also supports proactive vegetation management. With its fine spatial resolution, LiDAR can isolate and quantify tree heights within the pipeline right-of-way. This allows targeted pruning of vegetation that could interfere with pipeline operation, avoiding blanket clearing and preserving biodiversity.

Downstream operations involve some of the most complex industrial environments—dense with legacy piping, machinery, and structural elements. Unfortunately, many facilities operate with outdated or incomplete documentation, posing risks during retrofits or maintenance turnarounds.

Terrestrial LiDAR scanning solves this challenge by producing accurate “as-built” 3D models. Survey teams use tripod-mounted scanners to capture billions of measurements across the facility. These are then merged through registration to produce a cohesive, dimensionally accurate digital replica of the physical plant—often referred to as a digital twin.

This digital twin becomes an essential planning and engineering tool. Engineers can simulate modifications within the virtual plant environment, overlaying new CAD elements to perform clash detection and spatial verification. This ensures that proposed installations—pipes, vessels, conduits—fit seamlessly into existing infrastructure, avoiding costly field modifications.

During shutdowns and maintenance turnarounds, LiDAR’s value is even more apparent. Contractors can design scaffolding in advance, validate equipment transport paths, and choreograph maintenance sequences with precision. Time savings from accurate pre-planning directly translate into reduced downtime—critical when a single day offline can cost millions.

| Sector | LiDAR Application | Purpose / Outcome | Benefits |

|---|---|---|---|

| Upstream | Digital Elevation Models (DEMs) for seismic survey planning | Accurate terrain modeling to optimize geophone placement | Enhanced subsurface imaging; reduced survey error |

| Detection of subtle surface features (e.g., faults, reefs, drainage patterns) | Support geological interpretation in difficult terrains | Improved prospecting accuracy; higher exploration ROI | |

| Terrain mapping for road, pad, and infrastructure layout | Optimize access routes and minimize environmental footprint | Reduced construction costs and permitting time | |

| Midstream | Pipeline corridor mapping and route optimization | Topographic analysis for efficient, compliant route selection | Lower CAPEX; improved safety and operational efficiency |

| Monitoring terrain changes and detecting geohazards | Early identification of landslides, erosion, or subsidence near pipelines | Proactive risk mitigation; avoidance of spills or ruptures | |

| Vegetation management within right-of-way | Identify high-risk vegetation for targeted removal | Reduced maintenance costs; improved environmental stewardship | |

| Downstream | Terrestrial 3D scanning of facilities | Create accurate “as-built” models (digital twins) of complex infrastructure | Better planning, retrofitting, and clash detection |

| Virtual design verification and shutdown planning | Simulate scaffolding, retrofits, or maintenance workflows | Reduced downtime; safer and more efficient operations | |

| Integration with CAD and BIM systems | Overlay engineering designs on real-world models | Minimized rework; accelerated project delivery |

DJI Matrice 350 RTK LIDAR Pack is designed for complex operations and provides a comprehensive, high-efficiency solution for aerial LiDAR surveying in the oil and gas sector. This all-in-one system is ideal for 3D mapping and precision inspections across demanding environments, including upstream, midstream, and downstream sectors. Equipped with a high-accuracy LiDAR module and a 20MP RGB camera, it is well-suited for topographic mapping and the generation of detailed 3D models.

LiDAR has become a major data-driven decision-making technology across the oil and gas sector. Whether mapping rugged terrain in upstream phases, safeguarding critical midstream infrastructure, or simulating maintenance at refineries, LiDAR enhances operational clarity and cost-efficiency.

With the next-generation solutions like the DJI Matrice 350 RTK with LIDAR L2 Combo Pack, organizations can deploy high-precision LiDAR surveys with minimal personnel and maximum data fidelity. Integrated with processing software such as DJI Terra Pro, this turnkey solution accelerates project timelines, enhances safety and ensures smarter, more sustainable operations.

As LiDAR continues to evolve alongside AI and analytics, it’s poised to redefine how the oil and gas industry visualizes, plans, and executes across its full operational lifecycle.