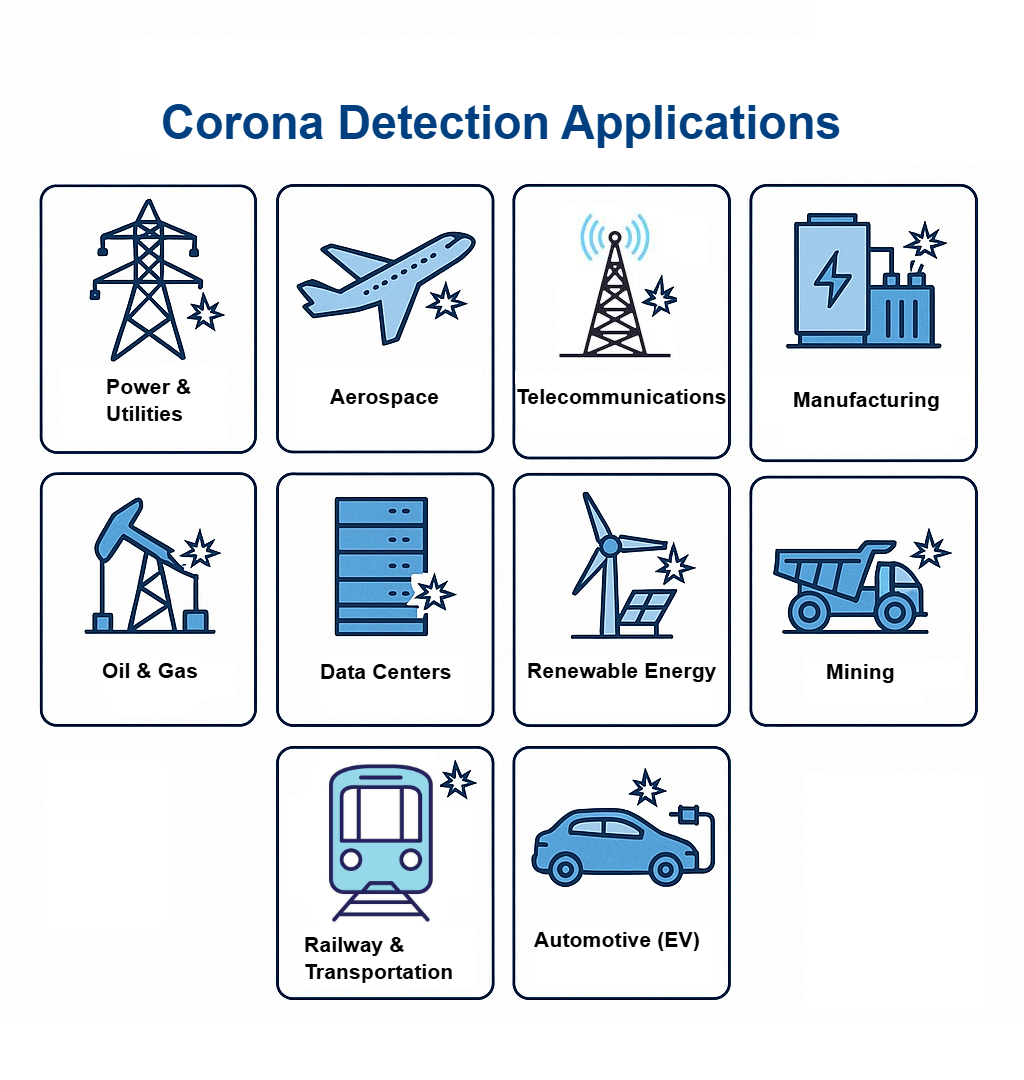

In this day and age, almost all of the industry sectors (e.g. power & utilities, mining, oil & gas, manufacturing, transportation, and telecommunication) depend on reliable power supplies. The reliability of the power supplies can be interrupted by a variety of factors, including technical, environmental, and human-related causes.

Technical failures are a major contributor to power supply interruptions in industrial sectors, often resulting in significant operational and financial losses. In the U.S. alone, downtime from electrical equipment failure costs industry over $150 billion annually (as per Bloomenergy). Generally, most of the unplanned outages are linked to technical issues such as faulty breakers, insulation degradation, or aging infrastructure. According to this ABB survey, In manufacturing plants, unplanned electrical outages can lead to production losses of about $125,000 per hour, underscoring the importance of preventive maintenance and system modernization to ensure reliability.

Among the lesser-known but critical technical issues affecting power reliability is corona discharge, a phenomenon that occurs when the electrical field around a conductor exceeds a critical threshold (often ~30 kV/cm), ionizing the surrounding air. This effect is particularly problematic in high-voltage systems, where it can lead to insulation degradation, electromagnetic interference, and even equipment failure over time. While often overlooked during routine inspections, corona discharge can accelerate the aging of components such as insulators, transformers, and switchgear, which compromises the system’s integrity and contributes to unplanned outages.

Corona discharge affects power lines efficiency in several measurable ways:

Therefore, identifying and mitigating corona discharge is essential for maintaining the long-term reliability of industrial power systems.

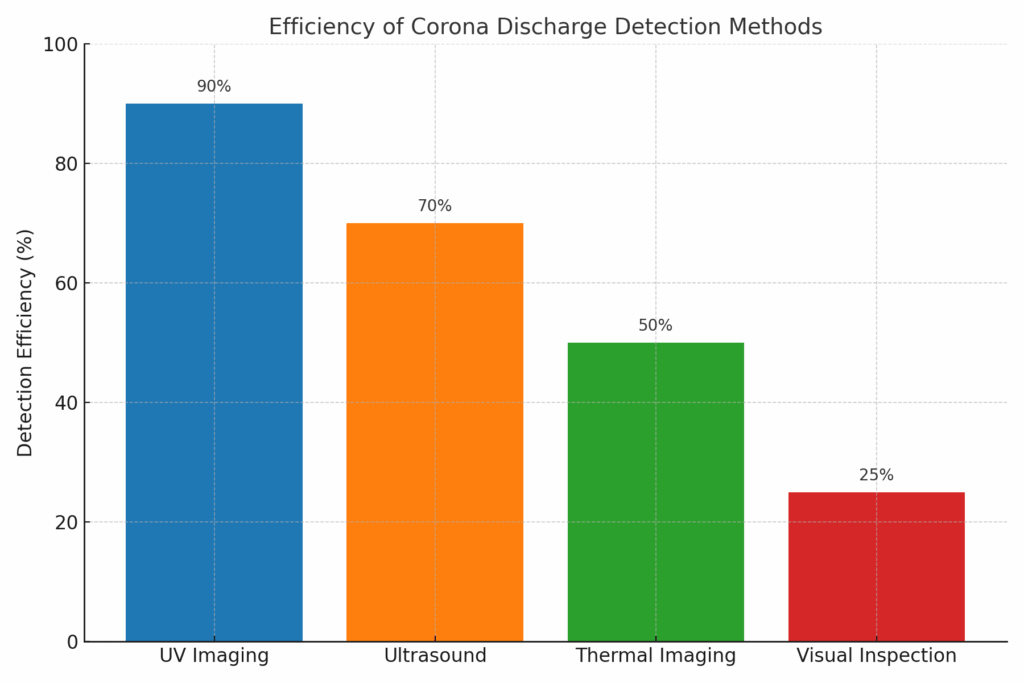

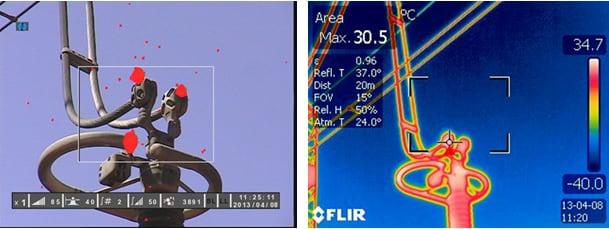

There are various methods that can be used to detect corona discharge; these methods include manual inspections using visual inspections, ultraviolet (UV) cameras inspections ultrasonic detectors, radio frequency (RF) detectors, chemical detectors, and thermal imaging. The advancement of drone technologies led to efficient drone-based solutions. Drones can carry various cameras and sensors, enabling precise, remote detection of corona activity without interrupting the systems operations or exposing personnel to risk.

As introduced in this article, UV imaging is uniquely critical for detecting corona discharge. UV imaging solutions are the most efficient and accurate solutions to detect corona discharge. As shown in the following figures, UV imaging offers the highest efficiency for non-contact, real-time corona detection, especially in outdoor and energized systems, without interrupting operations.

| Industry | Applications | Challenges | UV imaging solutions | Benefits |

|---|---|---|---|---|

| Power & Utilities | Inspecting transformers, substations, power lines, cables and insulators |

|

| Prevent insulation failure, reduce outages, and extend equipment life |

| Aerospace | Aircraft electrical system inspection |

|

| Ensure flight safety, avoid in-flight failures |

| Telecommunications | Inspecting radio frequency (RF) antennas and towers |

|

| Prevent RF interference, protect communication equipment |

| Manufacturing | Testing switchgear, insulators, and cables |

|

| Avoid unexpected shutdowns and improve safety |

| Railway & Transportation | Inspecting overhead lines and traction substations |

|

| Reduce breakdowns, enhance safety and reliability |

| Automotive (Electric vehicles (EV) sector) | Inspecting high-voltage cables and battery systems |

|

| Reduces breakdowns, enhances safety and reliability |

| Oil & Gas | Inspecting motors and transformers in explosive zones |

|

| Prevent ignition, ensure safe operations |

| Mining | Inspecting substations powering mining facilities |

|

| Prevent ignition, ensure safe operations |

| Data Centers | Monitoring uninterruptible power supply (UPS), switchgear, and cabling |

|

| Prevent outages, maintain uptime |

| Renewable Energy | Inspecting wind turbine and solar panel connections |

|

| Reduce downtime, improve energy yield |

As mentioned, UV imaging solutions (whether using handheld or drone-based cameras) are the most efficient in detecting corona discharge. Nevertheless, it is important to choose the right and suitable device for the specific application.

For example, for close daytime inspections of electrical apparatuses in/outdoors, one can use UVollé corona cameras. They are suitable for on-site testing of high & medium voltage apparatuses, for seeing pinpointed information about corona partial discharge, and for recording videos with corona discharge. UVollé corona cameras reveal and display in real-time existing voltage related faults.

On the other hand, drone-based solutions are the suitable solutions when inspecting infrastructure in hard-to-reach or hazardous areas. An example of UV cameras suitable for drone-based solutions is DayCor® micROM HD Solar Blind UV Camera, which is specifically designed to detect and pinpoint corona and arcing. It’s compact, lightweight, features a wide field of view and high – definition (HD) imaging. With its electromagnetic shielding, it ensures optimal performance even in the most demanding conditions. Its easy integration on UAVs, combined with the ability to integrate with various gimbals enhances its practicality and versatility.

In today’s interconnected and electrified industrial landscape, the early detection and mitigation of corona discharge have become indispensable for ensuring operational reliability, safety, and efficiency. This often-overlooked phenomenon poses significant risks to high-voltage systems across various sectors, from power utilities to aerospace and telecommunications.

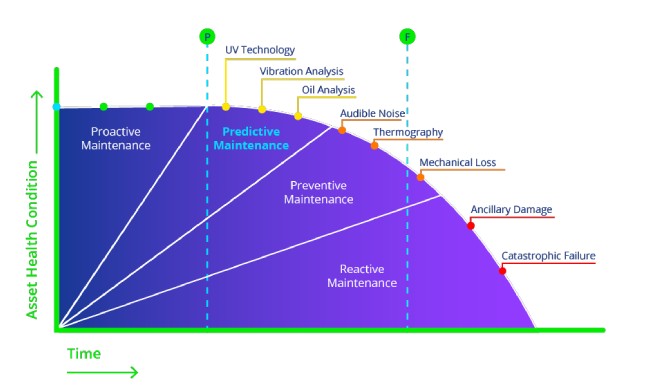

Ultraviolet (UV) imaging has proven to be the most effective method for real-time detection of corona discharge. Whether deployed through handheld devices for localized inspections or integrated with drones for remote and large-scale infrastructure monitoring, UV cameras provide unparalleled accuracy and real-time visualization of discharge events. Their integration into routine maintenance and diagnostic practices enables companies to adopt a predictive maintenance approach, which enhances the resilience, reduces downtime, prevents costly failures, and optimizes assets life cycles.