Unmanned Aerial Vehicles (UAVs), or drones, are increasingly used in inspecting electric power systems due to their efficiency, safety, and ability to access hard-to-reach components. Their applications on power systems span across generation, transmission, and distribution segments, including renewable and non-renewable energy industries. This article introduces the reader to various aspects of drone-based inspection for grids infrastructure, with a focus on the visual, thermal and corona camera inspection of power lines.

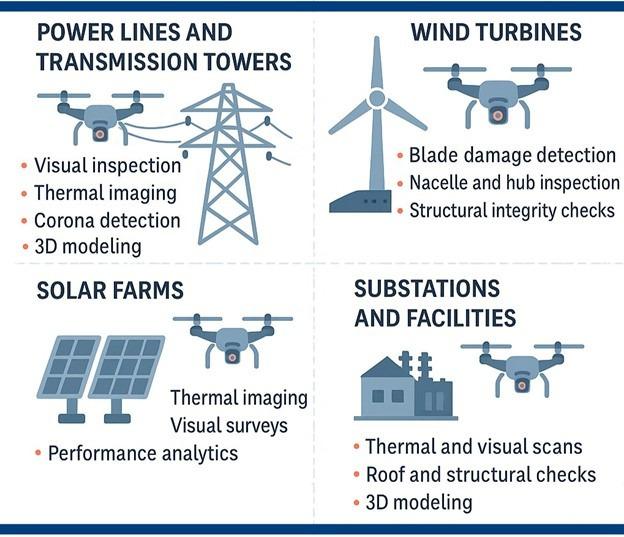

The key applications of drones in power systems could be categorized based on the part under consideration:

Traditional power line inspection methods have long faced significant challenges. These inspections typically rely on manual ground patrols and manned helicopters; the first approach is labor-intensive and time-consuming, while the second one is generally costly, noisy, and poses significant safety risks. These conventional approaches often prove inefficient, particularly in remote, mountainous or forested regions, or in harsh climatic environments, where access is difficult and risks are heightened.

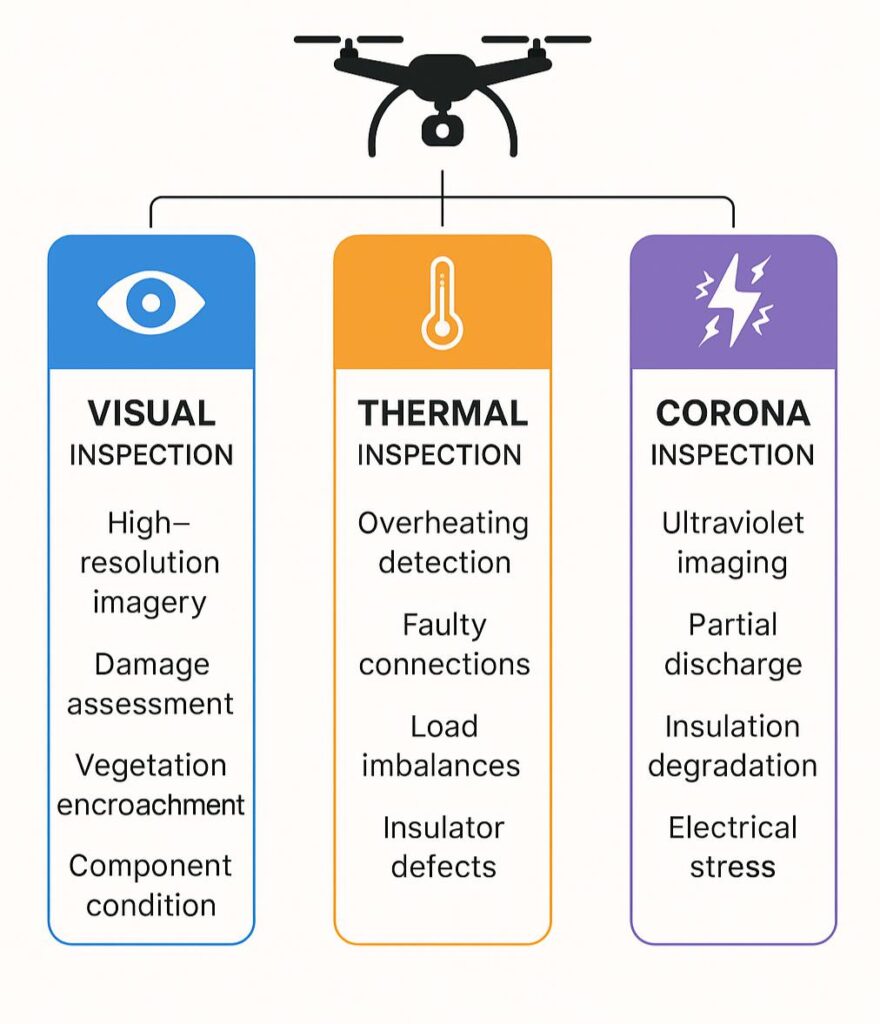

In this context, drone systems have become an important alternative for power line inspections due to their ability to improve safety, efficiency, and cost-effectiveness, compared to the aforementioned traditional approaches. These systems employ various sensors, including optical cameras, thermal imaging, and corona cameras, to collect comprehensive data on the infrastructure under consideration. The main areas where drone-based solutions are efficiently applied include inspection and fault detection.

Equipped with high-resolution optical cameras, drones, such as M350 RTK, can capture detailed images and videos of critical infrastructure components including insulators, conductors, towers, and hardware connections. These visuals allow for the identification of damage, corrosion, loose fittings, vegetation encroachment, and other anomalies that may compromise system reliability. Unlike manual inspections, drones can cover large distances quickly and access remote or hazardous locations with minimal risk to personnel.

In addition to enhancing safety and efficiency, drone-based inspections support data-driven maintenance strategies. The visual data collected can be processed using an appropriate software package, such as DJI Terra; specialists can also implement artificial intelligence (AI) and machine learning algorithms to automatically detect faults and prioritize repairs. Drones can also perform routine inspections more frequently than traditional methods, helping utility companies move from reactive to predictive maintenance models. This improves grid reliability, reduces downtime, and lowers operational costs while minimizing environmental impact from ground vehicles or helicopters.

“Overall, the M300 RTK with Zenmuse H20 Series payload has increased our efficiency by at least 30 percent. This means that this drone is not just a purchase for us; it’s an investment that would pay for itself.” – Jake Lahmann, Quality – UAS Manager, Valmont Utility

Drones equipped with thermal imaging cameras are increasingly used for the inspection of power and transmission lines, providing critical insights into the thermal behavior of electrical components. These inspections help identify overheating connections, faulty insulators, unbalanced loads, or deteriorating conductors—issues that might not be visible during standard visual inspections but can lead to equipment failure or power outages if left undetected. By capturing infrared images and thermal video from the air, drones can quickly survey extensive power networks without the need to shut down operations or dispatch crews to potentially dangerous heights.

Thermal drone inspections are especially valuable for preventive and predictive maintenance. The data gathered allows utilities to detect early signs of electrical stress or degradation, prioritize maintenance activities, and avoid costly emergency repairs. Combined with Global Positioning System (GPS) and analytics software, drones can also map hot spots over time, enabling historical comparisons and trend analysis. This enhances decision-making, improves system reliability, and extends the life of critical assets – all while reducing inspection time, cost, and safety risks for field personnel.

Corona discharge _ a partial discharge caused by ionization of the air surrounding conductors _ can indicate insulation degradation or equipment failure risks in power transmission systems.

Corona discharge affects power line efficiency in several measurable ways:

Therefore, corona detection is important, as it improves the efficiency and reliability of power lines. Traditionally, corona detection involved manual inspections using handheld ultraviolet (UV) or ultrasonic detectors, which are labor-intensive, time-consuming, and potentially hazardous. Drones, however, can carry UV cameras, ultrasonic sensors, or radio frequency (RF) detectors, enabling precise, remote detection of corona activity without interrupting operations or exposing personnel to high-risk environments.

Drone-based inspection using visual, thermal, and corona cameras represents a transformative shift in how power lines and grid infrastructure are monitored and maintained. By offering safer, faster, and more cost-effective alternatives to traditional inspection methods, drones enhance operational efficiency, reduce downtime, and support proactive maintenance strategies, which leads to achieving smarter, more reliable, and resilient energy networks.