The mining industry, one of the world’s most critical sectors, is undergoing a dramatic transformation through the integration of drone technology. As mining companies face increasing pressure to improve safety, reduce costs, and enhance operational efficiency, unmanned aerial vehicles (UAVs) have emerged as game-changing tools that address longstanding challenges while opening new possibilities for the future of mining.

Mining operations have historically relied on labor-intensive, time-consuming, and often dangerous methods for surveying, monitoring, and data collection. Traditional ground-based surveys can take weeks or months to complete, creating significant delays in project timelines and limiting access to critical areas due to safety concerns. The reliance on helicopters and large ground crews for aerial inspections has resulted in sky-high operational costs, while manual surveying methods often produce data gaps and inaccuracies that compromise decision-making capabilities.

Perhaps most critically, conventional mining practices expose workers to numerous hazards including landslides, mine collapses, and exposure to harmful substances. The inability to monitor dangerous areas in real-time has historically placed personnel at unnecessary risk while limiting companies’ ability to respond quickly to changing geological and environmental conditions.

Drone technology is fundamentally reshaping how mining companies approach their operations, offering solutions that are faster, safer, and more cost-effective than traditional methods. Modern mining drones are equipped with advanced sensors, high-resolution cameras, and sophisticated data processing capabilities that deliver unprecedented accuracy and efficiency.

Mining drones operate at speeds up to 30 times faster than ground-based inspections, dramatically reducing the time required for site surveys and data collection. This enhanced speed allows for more frequent monitoring and enables mining companies to conduct surveys on an as-needed basis, providing the flexibility to respond rapidly to changing site conditions.

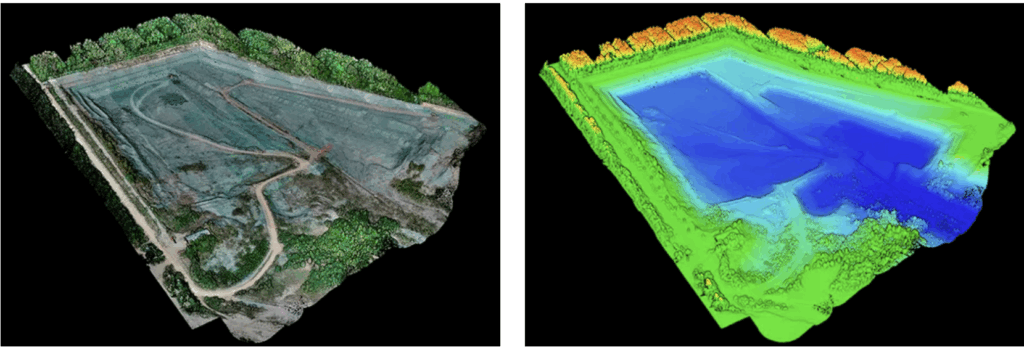

Advanced drone sensors capture high-resolution images and videos that surpass the capabilities of ground-based sensing technology. The unique aerial perspective allows for data point collection that is simply not feasible with traditional inspection techniques, while the large volume of data points collected improves overall accuracy and reduces margins of error in critical measurements like stockpile volumes.

Drones can access hard-to-reach or hazardous areas without risking worker safety, providing complete site coverage that was previously impossible or extremely dangerous to achieve. This capability ensures that no area of a mining operation goes unmonitored, improving both safety and operational oversight.

| Application | Benefit |

|---|---|

| 3D Mapping and Surveying | Drones equipped with advanced sensors create precise topographic maps and detailed 3D models of mining sites. These accurate representations are essential for planning mining operations, optimizing resource allocation, and ensuring safe, cost-effective extraction processes. |

| Stockpile Management and Volume Measurement | One of the most valuable applications of drone technology is in stockpile monitoring and inventory management. Drones can quickly and accurately measure volumes of stockpiles, excavations, and other materials, providing crucial data for inventory management, production planning, and financial reporting. This capability enables grade maximization through ore blending and provides production backup during supply disruptions. |

| Safety Inspections and Risk Assessment | Drones conduct comprehensive safety inspections of dangerous areas including open pits, high walls, and tailings dams. Equipped with thermal imaging and other advanced sensors, they can identify potential risks at an early stage while providing real-time data to safety teams, keeping workers out of harm’s way. |

| Environmental Monitoring and Compliance | Mining drones capture critical environmental data related to air quality, water levels, and vegetation health, helping companies maintain compliance with environmental regulations. This monitoring capability allows mining operations to track their ecological impact and implement necessary adjustments to minimize environmental damage. |

| Infrastructure Inspection and Maintenance | Drones inspect critical mining infrastructure including conveyor belts, pipelines, and processing plants, identifying wear and tear, potential failures, or maintenance requirements before they become critical issues. This proactive approach prevents costly breakdowns and ensures continuous operations. |

| Exploration and Resource Management | UAVs assist in exploring new mining sites and managing existing resources through detailed aerial surveys and data analysis. This capability helps mining companies locate prospective resource pools and optimize their extraction processes. |

| Security and Surveillance | Drones perform security patrols instead of requiring large security teams, providing cost-effective surveillance capabilities that save both time and money while maintaining comprehensive site security. |

While drone integration offers tremendous benefits, mining companies must address several challenges to maximize their investment:

Flight Time and Range: Large, remote mining sites require drones with extended flight capabilities. Advanced systems like automated charging and deployment stations enable prolonged, around-the-clock operations.

Data Management: The vast amounts of data generated by drones require sophisticated management and analysis systems. Integration with enterprise resource planning (ERP) systems ensures that drone data supports efficient, data-driven decision-making across the organization.

Skills and Training: Effective drone operation requires specialized skills in piloting and data analysis. Mining companies must invest in comprehensive training programs to develop internal expertise.

Regulatory Compliance: Drone operations must comply with aviation authority regulations, requiring proper permits and approvals that vary by region and country.

Mining security represents a critical challenge for the industry, particularly in protecting high-value assets from theft, illegal access, and intentional damage. The limitations of manual patrols across difficult terrain and vast mine areas often render traditional surveillance methods ineffective. Modern drone technology offers a comprehensive solution to these security challenges.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

The DJI Dock 3 system represents the pinnacle of automated mining security technology, offering non-stop surveillance capabilities even during night operations and extreme weather conditions. This comprehensive security solution consists of three integrated components:

DJI Dock 3 serves as the intelligent drone station, performing automated takeoff, landing, and battery charging operations without human intervention.

DJI Matrice 4TD for Dock 3 functions as the primary surveillance drone, equipped with advanced zoom and thermal cameras for long-range threat detection capabilities.

DJI FlightHub 2 operates as the cloud-based platform managing mission control, live streaming, and comprehensive data analysis. For detailed review of DJI FlightHub2 update, check our previous article.

This integrated system enables continuous 24/7 automatic mine monitoring, providing several critical capabilities including real-time monitoring of large mining areas without requiring additional security posts or personnel, protection of assets and heavy equipment from theft and vandalism in remote locations, and centralized operational activity monitoring to ensure all activities proceed safely and efficiently.

The DJI Dock 3 system offers five essential features specifically designed for mining security applications:

24/7 Automatic Patrol: Conducts monitoring missions around the clock, maintaining surveillance even during night hours, heavy rain, or other extreme environmental conditions.

Early Detection of Suspicious Activity: Advanced thermal and zoom cameras identify vehicle or human movement in real-time from significant distances, enabling rapid response to potential security threats.

Fast Charging & Continuous Operations: The system charges drone batteries from 15% to 95% capacity in just 27 minutes, enabling continuous patrol rotations without operational gaps.

Extreme Weather Resistance: With IP56 rating and operational temperature range from -30°C to 50°C, the system withstands harsh mining environments and challenging terrain conditions.

Cloud Integration: FlightHub 2 enables comprehensive monitoring, mission control, and live video access through a single browser-based cloud platform accessible from any control center.

Mining mapping faces numerous traditional challenges including inaccurate mapping results, incomplete area coverage, and lengthy data processing times. These issues often result in poor decision-making and potential operational losses. The SHARE UAV oblique camera system addresses these challenges through innovative multi-angle capture technology.

Unlike conventional cameras that capture images only from perpendicular angles, oblique cameras simultaneously capture images from five directions – one vertical and four diagonal perspectives. This comprehensive approach ensures that every object is visible from multiple angles, clearly capturing both vertical and horizontal details.

The SHARE PSDK 102S V3, combined with the latest generation DJI M350 RTK drone, provides optimal results through superior flight stability, maximum image quality, and seamless system integration. The collected data processes into highly accurate 3D models with precision levels of ±3 cm horizontally and ±5 cm vertically.

The DJI Matrice 4E Aerial Photogrammetry and Ground Surveying Bundle with South GNSS represents a complete solution for high-precision aerial photogrammetry and ground surveying tasks. This comprehensive bundle combines the next-generation DJI Matrice 4E drone platform with a complete South GNSS base and rover set, delivering superior flight performance, extended endurance, and centimeter-level positioning accuracy.

The system proves ideal for topographic mapping, site modeling, land development, and infrastructure planning applications. When paired with South GNSS’s reliable RTK/PPK receivers, it ensures robust positioning capabilities both in air and ground operations. The bundle includes Agisoft Metashape software for detailed post-processing, 3D reconstruction, and georeferenced outputs, supporting large-scale survey missions with exceptional accuracy and efficiency.

LiDAR sensor technology spans various operational stages in mining, from initial exploration through ongoing resource management, delivering critical capabilities across multiple applications.

Stockpile Volume Calculation: LiDAR sensors measure material volumes in stockpiles with exceptional accuracy, enabling fast and precise calculations for materials including coal and metal ore while significantly reducing manual calculation errors.

Land Deformation Monitoring: These sensors monitor ground movement in mining areas, particularly in regions prone to landslides, providing essential data for disaster prevention and operational safety assurance.

Topographic Mapping for Mine Planning: LiDAR generates detailed 3D topographic maps that facilitate efficient planning for transportation routes, drilling locations, and mining areas, proving especially valuable in difficult-to-access or complex terrain situations.

The implementation of LiDAR technology in mining operations delivers five primary advantages:

Speed and Efficiency: LiDAR accelerates mine survey processes, completing area mapping that traditionally requires weeks of manual work in just days.

Exceptional Accuracy: LiDAR systems produce data with precision levels reaching within centimeters, enabling highly accurate material volume calculations and operational planning.

Enhanced Safety: Aerial LiDAR surveys eliminate worker exposure to hazardous terrain, significantly reducing operational safety risks.

Cost Optimization: The technology reduces manual survey costs while allowing personnel to focus on other critical operational tasks.

Continuous Monitoring: LiDAR enables ongoing monitoring of mine area changes, including ground deformation detection through regular topographic data updates.

The DJI Matrice 350 RTK LIDAR Pack is designed for complex mining operations. It includes the DJI Matrice 350 RTK drone and the Zenmuse L2 LIDAR, with 55 minutes of flight time and a payload capacity of 2.7 kg, making it ideal for 3D mapping and precision inspections.

GNSS.AE, as the official DJI Enterprise dealer in the Middle East and Africa, provides comprehensive automated drone-based solutions for various industrial sectors, including mining. Our expertise encompasses the complete range of professional drone applications, from security and surveillance to precision mapping and surveying, ensuring mining companies have access to cutting-edge technology and professional support services.

As drone technology continues to evolve, its role in mining operations will only expand. The combination of improved safety, reduced costs, enhanced accuracy, and real-time monitoring capabilities makes drones indispensable tools for modern mining companies. From eliminating the need for costly manned aircraft to providing unique data perspectives impossible with traditional methods, drones are not just improving existing processes – they’re enabling entirely new approaches to mining operations.

The integration of advanced systems like automated security platforms, precision oblique cameras, comprehensive photogrammetry solutions, and LiDAR technology represents a fundamental shift toward safer, more efficient, and environmentally conscious operations. As companies continue to integrate these advanced systems into their workflows, the benefits will compound, creating a new standard for mining excellence that prioritizes both operational success and worker safety.