As the global energy transition accelerates toward renewable sources, wind energy has emerged as a cornerstone of sustainable power generation. This rapid expansion has elevated blade inspections from routine maintenance tasks to critical operations that determine the success and profitability of wind farms worldwide. The introduction of advanced monitoring technologies, particularly drone-based inspection systems, is transforming how the wind industry approaches asset maintenance and operational efficiency.

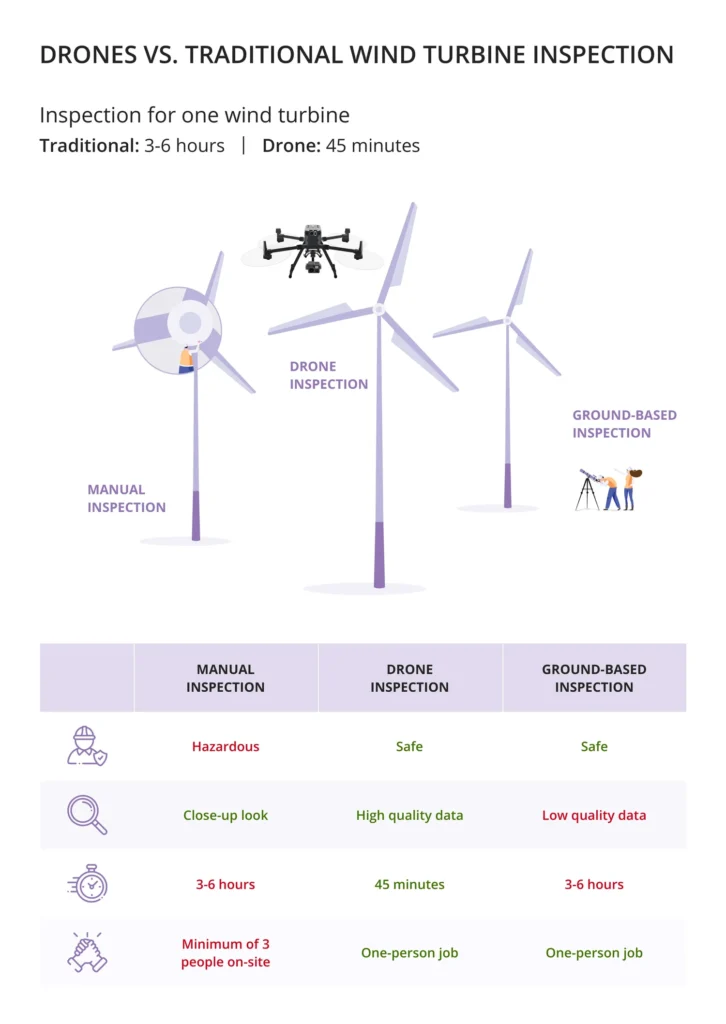

Traditional wind turbine inspection methods have long posed significant challenges for operators. Manual inspections requiring workers to climb towering structures or use rope-access techniques not only present substantial safety risks but also result in extended downtime and high operational costs. Thea wind industry has recognized these limitations and embraced a technological revolution that promises to address these concerns while delivering superior inspection results.

The commercial adoption of unmanned aerial vehicles (UAVs) has fundamentally transformed data acquisition techniques across numerous industries, with the wind sector being among the most enthusiastic early adopters. Modern drone systems, enhanced with artificial intelligence and machine learning capabilities, offer comprehensive solutions for monitoring wind turbines and their associated infrastructure.

These advanced systems deliver multiple advantages over conventional inspection methods. By removing workers from hazardous situations, drones significantly improve on-site safety while simultaneously reducing maintenance costs, inspection expenses, and minimizing turbine downtime. The technology represents a perfect intersection of safety, efficiency, and cost-effectiveness that the renewable energy sector has long sought.

Modern drone inspection systems deliver exceptionally detailed data that surpasses traditional methods in both clarity and resolution. High-quality cameras mounted on UAVs can capture aerial photographs and videos with resolution capabilities reaching up to 40 megapixels, providing unprecedented detail of entire blade surfaces. When combined with advanced technologies such as LiDAR (Light Detection and Ranging), operators can obtain precise measurements of defects and potential hazards that might otherwise go undetected.

This level of detail proves invaluable for asset maintenance and productivity retention. The precision achieved through UAV technology consistently outperforms other inspection techniques, establishing a new standard for wind turbine monitoring excellence.

The inspection process extends far beyond simple data collection. Once drone data is acquired, it undergoes sophisticated automated processing and classification systems. Industry specialists manually review the information to ensure quality standards and evaluate significant concerns regarding wind turbine infrastructure. Data is often transformed into three-dimensional models and other visual representations that facilitate easy interpretation and analysis.

This comprehensive approach ensures that all potential issues are identified and properly documented, enabling prompt decision-making and effective asset maintenance strategies.

Processed inspection data is typically uploaded to secure online portals, allowing organizations to review findings and classify information according to their specific requirements. The accessibility of this data across multiple devices including smartphones, laptops, and tablets ensures that decision-makers can access critical information whenever and wherever needed.

The convenience extends to report generation, where comprehensive defect reports can be produced as PDF documents at the touch of a button. This streamlined approach makes drone-generated data notably simple to understand and interpret for stakeholders across all levels of an organization.

UAV inspection data is systematically organized and stored, enabling organizations to leverage historical information for future planning and analysis. This capability proves essential for activities such as progress monitoring and predictive maintenance strategies. Information is securely stored on protected portals accessible only to authorized personnel, allowing businesses to track changes over time and conduct comparative analyses for enhanced decision-making.

The safety and efficiency improvements delivered by drone technology represent perhaps the most compelling reasons for its widespread adoption in the energy industry. Maintenance crews can examine potential defects in detail without engaging in hazardous manual climbing techniques or rope-access methods. UAVs enable last-minute spot checks to be conducted quickly through aerial photography, prioritizing worker safety while minimizing wind turbine downtime without compromising information quality.

Surface inspection involves visual examination of wind turbine exteriors using various methodologies. Traditional approaches include rope-access methods where workers are suspended from nacelles or elevated platforms, ground-based observations using binoculars or telescopes, and drone-based inspections with stabilized camera systems.

These inspections excel at detecting external defects such as cracks, erosion, lightning damage, and adhesive debonding. While rope-access methods require extensive working hours per blade and result in higher costs, drone-based inspections provide rapid and efficient alternatives. However, it’s important to note that surface investigations have limitations in detecting internal defects within blade structures.

Condition monitoring systems provide continuous surveillance through high-quality sensors installed directly on turbines to detect potential defects. While these systems cannot pinpoint exact damage locations, they are often combined with other inspection methods for comprehensive detection and repair protocols.

Embedded sensors monitor natural vibration patterns and frequency trends that can indicate structural damage. However, this approach requires substantial investment as sensors must be installed on every wind turbine. Additional challenges include determining optimal installation timing, ensuring sensor longevity over approximately 20-year operational periods, and establishing effective data transmission, storage, processing, and interpretation protocols.

Modern wind farm operations employ diverse drone data acquisition techniques, generally classified into two categories: manual and automated approaches.

Manual flight techniques provide drone pilots with complete control over unmanned vehicles throughout inspection operations. This approach requires operators to possess comprehensive skills and experience necessary to acquire valid and reliable data from wind farms. Pilots must demonstrate expertise in capturing uniform, sharp photographs of all blade components while maintaining safety protocols.

When images are captured with consistent structure and frequency, data organization and processing for detailed analysis becomes significantly more manageable. This method proves particularly suitable for spot checks, such as identifying lightning damage or verifying completed repairs. While equipment expenses may be more limited compared to automated systems, manual operations still require high-quality professional gear equipped with RGB cameras and specialized sensors.

Automated drone technology represents the cutting edge of wind turbine inspection capabilities. These systems employ automated UAVs, LiDAR technology, and high-resolution cameras to consistently deliver superior quality information. Specially configured LiDAR sensors provide precise drone guidance during blade inspections, compensate for drift caused by unstable wind conditions, and manage flight velocity to minimize motion blur.

Automated systems enable UAVs to examine 100% of blade surfaces with exceptional accuracy. These drones operate using pre-developed software with three-dimensional flight plans powered by artificial intelligence and machine learning algorithms. This automation enables accurate, repeatable, and systematic turbine blade investigations while requiring pilots only to configure equipment, adjust camera settings for environmental conditions, and initiate inspection procedures.

The analysis of turbine inspection data requires specialized data engineering expertise to transform raw information into actionable insights. Given that drone operations can generate hundreds or thousands of images from wind farms, with each inspection producing substantial data volumes, sophisticated processing and analysis systems are essential.

Organized and sorted data undergoes advanced computational procedures using pattern recognition and artificial intelligence systems. Damage identification is automated and classified according to predetermined severity levels, enabling rapid assessment and prioritization of maintenance needs.

Data engineering professionals conduct comprehensive reviews to identify errors and perform thorough quality checks. Any discovered mistakes are processed again to improve automated processing system performance, creating a continuous learning environment that enhances accuracy over time.

Finally, blade specialists analyze identified damage and provide informed assessments regarding defect implications and potential improvement solutions. This expert analysis ensures that technical findings are translated into practical maintenance strategies and operational decisions.

Sulzer Schmid offers powerful data analytics through their 3DX™ Blade Platform, which provides autonomous blade inspection capabilities crucial for developing efficient operations and maintenance strategies. Their end-to-end process employs autonomous drones and incorporates cutting-edge image analysis tools within browser-based interfaces.

The platform generates comprehensive reports instantly while interactive dashboards allow users to filter data aspects for performance optimization. Their damage progression module supports predictive maintenance strategies, helping operators transition from reactive to proactive maintenance approaches.

SkyVisor provides comprehensive wind turbine blade drone inspection software designed to master predictive blade maintenance through automated visual data collection and AI-powered defect detection tools. This industry-leading solution empowers technicians to conduct turbine inspections independently using digital twin technology for blade health monitoring, asset management, defect comparison, and collaborative damage repair processes.

The software delivers insights for turbine performance optimization while identifying issues with exceptional speed and accuracy. By enabling early defect detection, facilitating collaborative repair processes, and optimizing maintenance strategies, SkyVisor represents the future of intelligent wind turbine monitoring.

Drone inspections have clearly established themselves as the preferred solution for numerous industries, with wind energy leading the adoption curve. The integration of UAV technology can significantly enhance wind farm operations while preserving asset value and extending operational lifespans.

As artificial intelligence, machine learning, and sensor technologies continue advancing, wind turbine monitoring systems will become even more sophisticated and capable. The combination of automated data collection, intelligent analysis, and predictive maintenance capabilities positions the wind energy sector for unprecedented levels of operational efficiency and reliability.

The evolution from traditional inspection methods to advanced drone-based monitoring represents more than a technological upgrade—it signifies a fundamental transformation in how the renewable energy industry approaches asset management, safety, and operational excellence. As this technology continues maturing, wind energy operators who embrace these advanced monitoring solutions will be best positioned to maximize their investments while contributing to the global transition toward sustainable energy generation.