The renewable energy sector is expanding at an unprecedented pace, with wind and solar installations rapidly spreading across remote and often challenging terrain. As asset portfolios grow, so does the complexity of inspection, maintenance, and performance optimization. Traditional inspection methods, reliant on manual access, specialized crews, and lengthy planning cycles, are increasingly unable to meet the sector’s demands for speed, safety, and consistency.

To address these challenges, Turkish energy company GÜRİŞ has transitioned from conventional inspection workflows to a fully automated drone-based solution powered by DJI Dock 3. This shift marks a significant step forward in how renewable energy assets are monitored and managed.

Wind turbines and solar power plants present fundamentally different inspection challenges. Wind turbine blade inspections typically require high-risk access procedures, specialized rope teams, and extended turbine downtime. Solar farms, on the other hand, demand the regular inspection of hundreds or even thousands of panels to identify defects, hotspots, or performance losses.

Each asset type requires distinct expertise, equipment, and scheduling, often resulting in fragmented workflows, inconsistent data quality, and long inspection timelines. In many cases, inspections can take four to twelve weeks, delaying critical maintenance decisions and increasing the risk of unplanned outages.

DJI Dock 3 provided GÜRİŞ with a robust foundation for automating both wind and solar inspections. Designed for remote and unattended operations, the system enables drones to be deployed, flown, and managed entirely off-site using standardized flight plans and procedures.

When combined with the company’s in-house inspection software, DJI Dock 3 created a seamless, end-to-end inspection workflow:

This integrated approach proved to be the most effective solution for addressing company’s most critical field challenges.

One of the most immediate and measurable benefits of the DJI Dock 3 deployment was the dramatic reduction in inspection timelines. Processes that previously took several weeks were shortened to just one to three days, enabling much faster decision-making and maintenance planning.

By reducing reliance on manual input, the automated workflow also minimized human error and ensured that inspection results were objective, repeatable, and standardized across all wind and solar sites. For asset managers, this translated into higher confidence in data quality and improved long-term asset performance tracking.

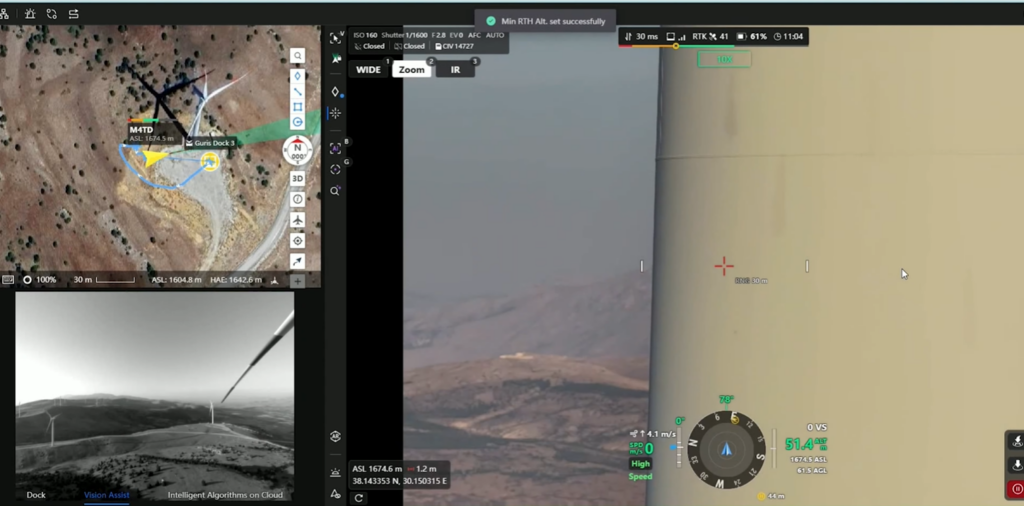

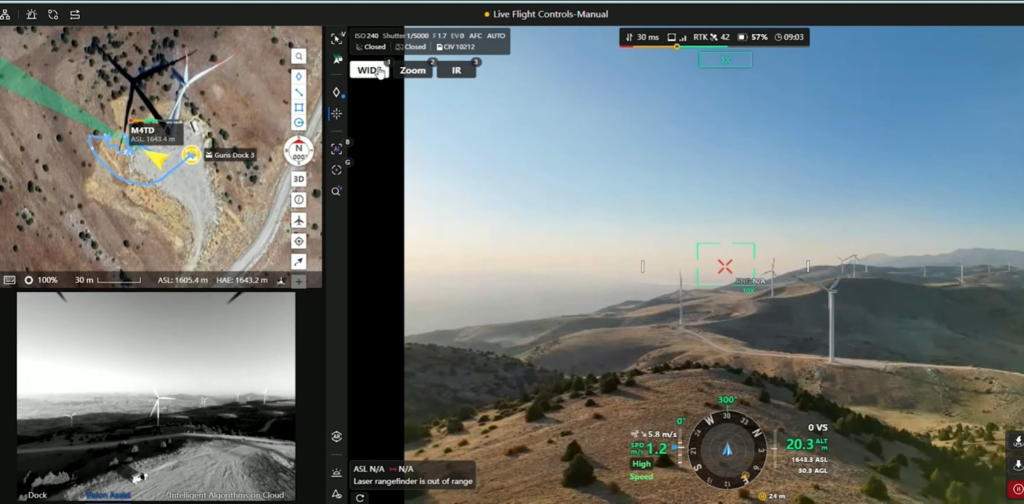

During early field deployments, the team observed how images captured by DJI Dock 3 were processed almost instantly by their analysis software. Critical wind turbine blade damage became visible to operators in real time, allowing field crews to respond immediately.

In one notable case, a serious blade defect was detected early and repaired before it escalated into an unplanned turbine shutdown, preventing significant production losses and costly downtime.

On the solar side, thermal inspections enabled accurate hotspot detection, directly contributing to measurable annual increases in energy output. By identifying underperforming or damaged panels early, maintenance teams were able to restore efficiency before losses accumulated.

Beyond performance gains, safety improvements were a key outcome of automation. High-risk manual inspections at height were largely eliminated, significantly reducing exposure to hazardous working conditions. With DJI Dock 3 handling routine inspections, teams could shift their focus from physically demanding fieldwork to higher-value strategic analysis and optimization tasks.

Automated flight capabilities combined with automated reporting further reduced the need for manual intervention, streamlining operations while maintaining a high level of inspection rigor.

Systems like DJI Dock 3 represent a critical milestone for renewable energy operators striving to scale efficiently while maintaining safety and reliability. By enabling autonomous inspections, standardized data collection, and rapid analysis, DJI Dock 3 is helping organizations like GÜRİŞ redefine how wind and solar assets are managed.

As organizations continue to invest in renewable energy infrastructure, automation will play an increasingly central role in ensuring sustainable growth, operational resilience, and long-term energy security. DJI Dock 3 is already demonstrating how that future is taking shape today.

Contact GNSS.AE team to explore how drone technoogy can elevate operations for your company.