As utilities modernize their infrastructure and accelerate digital transformation, UAV-based inspections have become a cornerstone of safe and efficient power system maintenance. To understand how aerial technologies are reshaping the sector, we spoke with Muhammad Bilal, an Electrical Engineer and UAV-Based Asset Inspection Expert based in Doha, Qatar.

Muhammad brings deep field experience across transmission, distribution, and substation environments, blending technical knowledge with real-world operational insights. Throughout our conversation, he shared not only his expertise but also the practical lessons learned from years of on-site inspection work.

Muhammad began his career performing inspections the traditional way, on foot and close to energized assets. He recalls:

“I started as an electrical engineer working on ground inspections for power assets. Over time I saw how UAVs reduced personal risk and improved visibility on defects that were hard to see from the ground.”

He explained that this realization motivated him to dive deeper into aerial systems, sensor payloads, and safe flight planning.

“The transition gave me better reach, safer workflows, and faster reporting,” he says, describing drones as a natural next step in modern inspection engineering.

Muhammad’s fieldwork spans multiple challenging environments, each with unique operational and maintenance demands.

“I have inspected high voltage transmission corridors, coastal substations with salt exposure, and desert grids with heat stress on components,” he notes.

His work on thermal load studies gave him firsthand insight into how defects behave under real operational conditions. Beyond fieldwork, Muhammad has also contributed to governance and policy.

“I build UAV policies and conduct compliance audits for ISO 21384-3 and ISO 27001. SORA and risk assessment work sharpened my understanding of safe flight planning,” he explains.

When asked why utilities are accelerating UAV adoption, Muhammad is clear:

“They reduce the need for climbing towers or sending teams close to energized parts. UAVs capture more accurate data, which helps identify defects earlier and prevent outages.”

He adds that drones deliver operational efficiency across long transmission routes.

“Utilities also save time and operational cost with consistent aerial data,” making UAVs a strategic asset for both maintenance and planning departments.

Traditional inspection workflows often require large teams, extended site time and physical exposure.

“Traditional work is slower and involves more physical risk for field crews,” Muhammad explains.

In contrast, drones simplify and accelerate operations.

“UAVs finish the same work in less time with higher precision. They also reduce the number of people needed onsite because the drone does most of the reach work,” he adds.

The overall result: better safety, higher speed, and improved cost control.

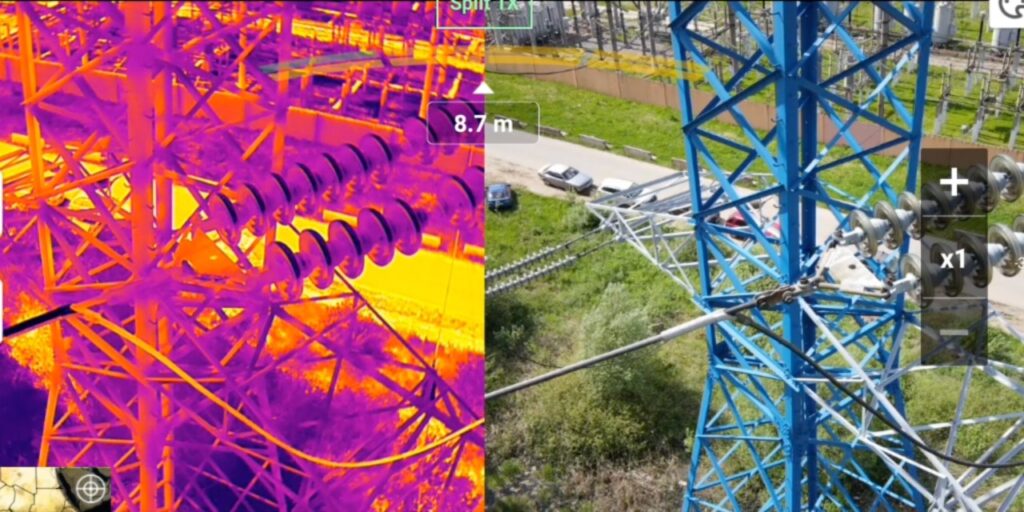

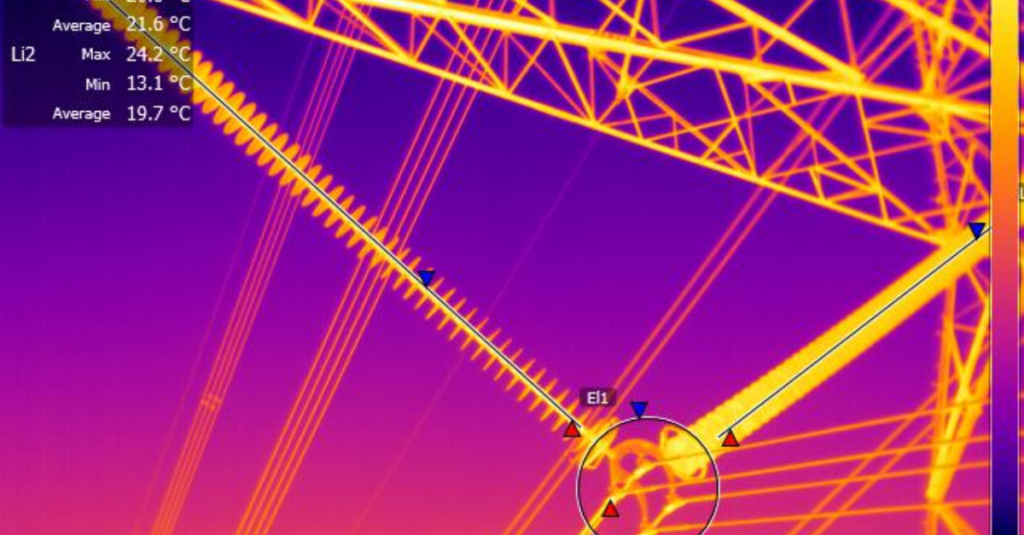

Muhammad emphasizes the importance of a multi-sensor approach:

“RGB provides clear visual evidence of physical damage like cracks or loose fittings. Thermal cameras reveal hotspots and abnormal load conditions. LiDAR delivers accurate clearance measurements and vegetation profiles.”

These three data streams allow utilities to assess structural, thermal, and spatial risks simultaneously.

Selecting the correct sensor suite depends on asset type:

“I match sensors to the type of defect I expect to find,” Muhammad says.

For example:

Transmission lines: “Thermal and zoom RGB to see hardware clearly.”

Substations: “LiDAR because clearance and equipment spacing matter.”

Transformers: “Thermal checks for internal heating.”

Flight parameters are also tailored.

“Flight speed, height, and angle are set based on data quality targets,” he adds.

Muhammad follows a structured and disciplined inspection methodology:

“I begin with site surveys, hazard checks, and needed permissions. Flight plans are prepared with safe distances and alternate paths for emergencies.”

During the mission, stability is a top priority.

“I focus on stable movement and complete coverage,” he explains.

Post-flight, all insights are consolidated.

“Once data is collected, I run QC, analyze findings, and build a clear, action-focused report.”

With energized components, risk awareness is essential.

“You need to maintain safe separation from conductors and equipment because arcs and EM fields can affect the drone,” Muhammad warns.

Environmental conditions, such as wind around transmission lines, require continuous attention.

“Wind can cause sudden shifts, so stability matters. Crew communication prevents mistakes.”

Muhammad highlights the importance of documentation and strict adherence to rules.

“I follow all authority rules including airspace limits, registration, and pilot certification,” he says.

For utilities, workflows must also align with internal protocols:

“Every mission has updated risk assessments and a full document trail. Utility protocols such as site briefings and supervisor approvals are followed strictly.”

Operating near high-voltage assets introduces navigational challenges.

“I keep the drone in open sight lines and avoid flying directly beneath conductors,” Muhammad explains.

To maintain accuracy:

“RTK improves positioning when satellites bounce signals. I monitor flight mode warnings and switch to manual if the drone becomes unstable. Careful path planning reduces signal reflection zones.”

High-quality data requires both planning and in-flight precision.

“Motion blur appears when flying too fast or in gusty wind. Poor angles hide defects. Shadows and low light reduce clarity, and insufficient overlap affects mapping accuracy,” he notes.

However, most of these issues can be addressed through careful pre-planning and controlled flight.

Muhammad is a strong advocate for data standardization.

“I export images, point clouds, or thermal maps in standard formats so they import cleanly,” he says.

Asset linking is handled through a structured workflow:

“Naming conventions and geotags help the utility link data to specific towers or bays.”

This allows digital twins to stay aligned with real-world asset conditions.

Across power grids, some issues appear frequently:

“Thermal hotspots, cracked insulators, corrosion, loose fittings, vegetation growth, and tower deformation,” Muhammad lists.

These problems, if left unaddressed, pose safety, reliability and operational risks.

Muhammad recalls a particularly difficult case from his experience:

“A coastal line had strong crosswinds and heavy salt buildup on insulators. Standard flight paths were unstable, so I flew lower and at angles that reduced drift.”

To maintain control and data quality:

“I broke the mission into short segments to keep battery and control margin high.”

The adapted strategy delivered clean, actionable results.

Muhammad sees rapid technological evolution ahead:

“AI will automatically classify defects and send alerts without manual review. Automated flights will run routine inspections, and aircraft will have longer endurance and more resistant frames.”

He also predicts tighter integration with digital twins:

“Real-time drone data will support predictive maintenance.”

For organizations beginning their drone journey, Muhammad advises a measured approach:

“Begin with a small pilot program and scale as confidence grows. Build in-house skills so the team understands both flying and data analysis.”

He underscores the importance of process discipline:

“Keep safety and documentation as core habits. Choose sensors based on actual asset needs, not on marketing claims.”

Through deep technical insight and hands-on field experience, Muhammad Bilal demonstrates how UAVs are elevating safety, accuracy, and efficiency in electrical asset management. His expertise highlights a clear message: drone-based inspections are no longer optional—they are essential tools for modern, reliable power system operations.